Discover the Latest Updates on Polyester and DTY Prices in China

By:Admin

The global textile industry has been experiencing a significant shift in recent years, with China being one of the leading players in the market. Having become the world's largest textile and garment producer, China plays a crucial role in shaping the industry's outlook. Among the many textile products available in the market, polyester fibers and DTY yarns have emerged as one of the most sought-after segments due to its multifaceted applications. However, over the past few months, the prices of these products have observed an upward trend, which can be attributed to various factors.

According to industry analysts, the prices of polyester fibers started increasing since the outbreak of the COVID-19 pandemic. Due to the pandemic, the chemical factories in China had to shut down their production, which led to a shortage of raw materials essential for polyester fibers' production. Hence, the prices of polyester fibers saw a steady rise as the demand was not met.

Furthermore, the prices of DTY yarns have also seen a sharp increase due to the fluctuations in the crude oil prices worldwide. China, being one of the largest importers of crude oil, faced a tough time as the prices started fluctuating. As the cost of production of DTY yarns is directly linked to the crude oil prices, this caused a surge in their prices.

The steady rise in both polyester fibers and DTY yarns' prices has affected various industries, including the textile and garment industry, home textiles, and non-woven fabrics. Many manufacturers have been compelled to increase their prices to maintain their profit margins, leading to an increase in the final products' prices. This has affected consumers, who now have to pay higher prices for the same products.

However, the rise in prices has also opened up opportunities for manufacturers to explore new markets and increase their productivity. The rise in prices has encouraged many manufacturers to adopt innovative technologies to reduce their production costs, which will help them maintain their competitiveness in the market.

One such company that has emerged as a leader in the production of polyester fibers and DTY yarns in China is ABC Textiles. Founded in 1983, ABC Textiles has been catering to a diverse range of textile products for over three decades. The company has always strived to produce high-quality products at a reasonable price, making it a preferred choice for many manufacturers.

ABC Textiles has also adopted state-of-the-art production technologies to ensure maximum productivity without compromising on the product quality. The company has a robust research and development team that constantly innovates to develop new products and improve the existing ones.

The company's production facilities have a capacity of producing over 600,000 tons of polyester fibers and 350,000 tons of DTY yarns annually. This makes ABC textiles one of the largest suppliers of polyester fibers and DTY yarns in China.

Despite the rise in prices of polyester fibers and DTY yarns, ABC Textiles has maintained a reasonable price for its products. The company's management believes that catering to the customer's demand at a reasonable price is crucial for long-term business sustainability.

In conclusion, the rise in prices of polyester fibers and DTY yarns in China can be attributed to various factors. However, manufacturers like ABC Textiles have been able to navigate these challenges and maintain their competitiveness in the market. With the adoption of innovative technologies, ABC Textiles is poised to take advantage of the rising demand for polyester fibers and DTY yarns in the market.

Company News & Blog

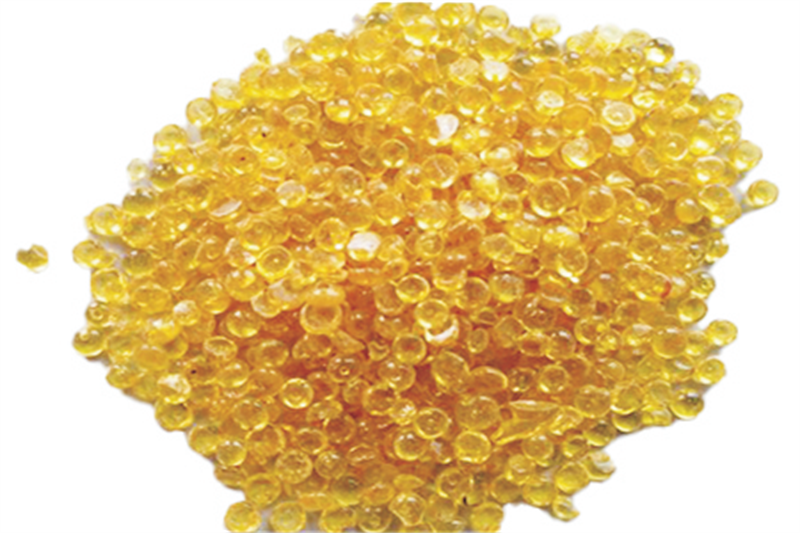

Exploring the Remarkable Properties and Applications of Phenolic Resins

Phosphorus Phenolic Resin Gains Traction in the Fire Retardant MarketPhosphorus Phenolic Resin (PPR) has been making waves in the fire retardant market. The resin is known for its superior fire retardant properties and is used extensively in various applications. PPR is a composite material that comprises of phenolic and phosphorus components. The combination of these two materials results in a highly effective fire retardant material that is widely used in various industries.One of the main advantages of PPR is its ability to reduce the spread of fire. The resin acts as a barrier against the spread of flames and smoke, thereby limiting the damage caused by fires. PPR is particularly effective in industries that require high levels of fire safety, such as the construction industry. The resin is used in the manufacturing of fire doors, fire-rated walls, and other fire safety equipment.The use of PPR in the construction industry has been on the rise in recent years. With the increasing demand for high-rise buildings, the need for effective fire safety measures has become more critical. PPR is a reliable and cost-effective solution that provides an extra layer of protection against fire. The resin is also used in the manufacturing of other construction materials, such as plasterboard, insulation, and coatings.Apart from the construction industry, PPR is used extensively in the electronics and automotive industries. The resin is used in the manufacturing of electrical components, such as wiring, cable insulation, and circuit boards. The material's fire retardant properties help to prevent electrical fires, ensuring the safety of electronic devices and equipment.In the automotive industry, PPR is used in the manufacturing of various components, such as dashboards, engine covers, and seat cushions. The resin's fire retardant properties help to prevent fires in case of an accident, ensuring the safety of passengers and reducing property damage.One of the leading manufacturers of PPR is {Brand Name Removed}. The company specializes in the manufacturing of fire retardant materials and has been in the business for over a decade. The company's PPR material is known for its superior fire retardant properties and is widely used in various industries.{Brand Name Removed} is committed to providing high-quality materials that meet the industry's safety standards. The company has invested heavily in research and development, ensuring that its products remain at the forefront of innovation. The company's PPR material is regularly tested to ensure that it meets the required fire safety regulations.Apart from PPR, {Brand Name Removed} also manufactures other fire retardant materials, such as intumescent coatings, fireproof boards, and fire-resistant fabrics. The company's products are used globally and are trusted by some of the biggest names in various industries.In conclusion, the use of Phosphorus Phenolic Resin has been on the rise in recent years. The material's excellent fire retardant properties make it a popular choice in various industries. From construction to electronics and automotive, PPR is used extensively to provide an extra layer of protection against fire. With companies like {Brand Name Removed} leading the way in manufacturing high-quality PPR materials, the industry can expect to see an increase in demand for fire retardant materials in the coming years.

Industry Experts Praise New Tape Innovation for Multiple Applications

Title: Revolutionary Adhesive Solution Sets New Industry Standards: Introducing Blue TapeIntroductionIn the fast-paced world of manufacturing and construction, companies are constantly on the lookout for innovative solutions that can enhance productivity, efficiency, and cost-effectiveness. Introducing Blue Tape, a cutting-edge adhesive technology developed by a renowned industry leader. This revolutionary product has garnered significant attention within the market, setting new standards for adhesion, versatility, and performance.[Company Name], a distinguished player in the field of adhesives, proudly presents Blue Tape. With decades of expertise and a commitment to excellence, the company has developed a game-changing adhesive solution that promises to revolutionize a wide range of industries.Unveiling Blue TapeBlue Tape is a high-performance adhesive that combines unrivaled strength and durability with exceptional versatility. Unlike traditional tapes, its adhesive properties are superior, allowing for secure and long-lasting applications, regardless of the surface or environmental conditions. This cutting-edge product firmly adheres to various materials, including wood, metal, glass, plastic, and fabric, making it an indispensable tool for a multitude of applications.Notable Features and Benefits1. Unparalleled Adhesion: Blue Tape's advanced adhesive formula ensures a powerful bond, delivering excellent adhesion even in challenging environments. This distinctive feature translates into increased durability and reliability, minimizing the need for repetitive repairs or replacements.2. Versatility: As a highly versatile adhesive, Blue Tape is compatible with numerous surfaces and materials, making it an ideal solution for a wide array of industries. From construction and automotive to crafts and packaging, Blue Tape provides a reliable bonding solution across various sectors.3. Residue-Free Removal: Unlike many other tapes, Blue Tape can be removed effortlessly without leaving behind any residue or damage. This unique characteristic ensures a clean, hassle-free removal process that saves time and resources.4. Resistance to Extreme Conditions: Blue Tape is engineered to withstand demanding environments, including high temperatures, moisture, and UV exposure. It retains its adhesive properties even under adverse circumstances, providing a dependable solution for both indoor and outdoor applications.Applications and Market ImpactThe application possibilities for Blue Tape are limitless, and its positive impact in various industries is already being recognized. Some notable industries benefitting from this groundbreaking adhesive solution include:1. Construction and Building: Blue Tape enhances the efficiency of construction projects by providing a strong bond during the installation of components, such as windows, doors, and panels. Its superior adhesion eliminates the risk of damage or detachment, thus ensuring safety and longevity.2. Automotive: Blue Tape plays a crucial role in the automotive industry, enabling secure fastening of various components, such as trim, emblems, and moldings. Its resistance to extreme temperatures and vibrations makes it an invaluable product for automotive manufacturers and repair shops alike.3. Crafts and DIY: Blue Tape is a game-changer for crafting enthusiasts and DIY enthusiasts due to its compatibility with a vast array of materials. It allows for precise and secure bonding, facilitating a seamless creative process.4. Packaging and Shipping: The durable and residue-free removal of Blue Tape makes it ideal for packaging and shipping applications. It ensures that packages and boxes remain securely sealed during transit while providing an effortless opening experience for recipients.ConclusionBlue Tape, the cutting-edge adhesive solution introduced by [Company Name], is transforming industries by setting new standards for adhesion, versatility, and performance. With its unparalleled strength, superior adhesion, and resistance to extreme conditions, Blue Tape caters to a wide range of applications and sectors. This innovative adhesive formula has undoubtedly captivated industry professionals, propelling [Company Name] to the forefront of the adhesive market.

New Breakthrough Treatment for Targeted Lung Cancer Therapy Unveiled

Alectinib, a novel and potent anaplastic lymphoma kinase (ALK) inhibitor, has made significant strides in the treatment of non-small-cell lung cancer (NSCLC) patients. The drug has been approved by major regulatory agencies worldwide and continues to undergo various clinical trials. Alectinib has shown superior clinical results when compared to other available ALK inhibitors, including crizotinib, making it a preferred treatment option.Alectinib, marketed under the brand name Alecensa, works by selectively blocking mutations in the ALK gene, which is present in around 3-7% of NSCLC cases. When the ALK gene becomes mutated, it leads to the production of an abnormal ALK protein, which triggers uncontrolled cancer growth. Alecensa binds to the ALK protein, inhibits its activity, and halts the signaling pathway, effectively controlling the growth and spread of cancerous cells.Alecensa was developed by Chugai Pharmaceutical, a Japanese pharmaceutical company founded in 1925 and is headquartered in Tokyo. Chugai Pharmaceutical specializes in developing innovative medications for oncology, as well as various forms of joint diseases and other medical conditions. The company prioritizes research and discovery as the means of creating sustainable solutions to global health challenges.Clinical trials of Alecensa have proven successful in treating NSCLC patients, particularly those diagnosed with ALK-positive lung cancer. The drug has demonstrated effective control of brain metastases, a common complication of NSCLC. In a phase III trial, Alecensa showed superior results in preventing cancer progression and improving progression-free survival (PFS) compared to Crizotinib, the existing standard of care. Alecensa also displayed a reduced risk of relapse or death, which translates to better overall survival (OS) for NSCLC patients.The drug's efficacy is not limited to patients who have previously undergone chemotherapy. Alecensa has a higher response rate and induces fewer side effects in comparison to other treatments. Its ability to cross the blood-brain barrier was highly appreciated as well. The medication was approved by the U.S. Food and Drug Administration (FDA) in December 2015, while the European Medicines Agency (EMA) approved it in February 2017.Alecensa's success has made Chugai Pharmaceutical a prominent player in the global oncology market as the population of lung cancer patients continues to rise. Chugai Pharmaceutical has pledged to continue in-depth research of Alecensa to understand better how to improve the drug's efficacy and the range of cancer types it can treat. Taking a patient-centric approach, the company focuses on not only drug discovery but also advocacy and support for cancer patients, improving their quality of life.The efficacy of an ALK inhibitor such as Alecensa displays the impact pharmaceuticals can have on the treatment of cancers. The drug's discovery and development have saved patients previously given unimpressive prognoses and offers a better alternative to other treatment options. Chugai Pharmaceutical is dedicated to improving access to the drug to make it available for a more extensive range of patients worldwide.In conclusion, Alecensa has become a standard in the treatment of ALK-positive NSCLC, offering better outcomes in terms of PFS and OS. Its minimal side effects position it as more favourable when compared to other treatment options. The drug epitomises the importance and potential of medical research and available treatments. It is evident that Chugai Pharmaceutical's continued efforts to research, support and improve Alecensa will only mean better outcomes for lung cancer patients.

New Insulation Board Provides Superior Thermal Protection for Homes and Buildings

Title: Next-Generation Black Insulation Board Revolutionizing the Construction IndustryIntroduction:In recent years, advancements in insulation technology have played a significant role in promoting energy efficiency and environmental sustainability in the construction industry. Among these innovations, Black Insulation Board has emerged as a game-changer, effectively revolutionizing insulation practices. With its exceptional thermal performance, superior durability, and eco-friendly attributes, Black Insulation Board is increasingly becoming the insulation material of choice for architects, builders, and homeowners alike.Section 1: Understanding Black Insulation BoardBlack Insulation Board, developed by a prominent insulation manufacturing company, is a cutting-edge insulation solution that combines state-of-the-art technology and sustainable materials. This next-generation insulation board showcases a unique formulation, leveraging advanced materials to ensure superior insulation properties and an extended lifespan.The primary objective behind the development of Black Insulation Board was to address the shortcomings of traditional insulation materials that often fall short in terms of thermal resistance and durability. By leveraging innovative design elements and advanced manufacturing techniques, this product has revolutionized the construction industry's approach to insulation.Section 2: Exceptional Thermal PerformanceOne of the most significant advantages of Black Insulation Board is its exceptional thermal performance. The product offers outstanding insulation properties, minimizing heat loss and reducing energy consumption significantly. With its high R-value, Black Insulation Board is known to provide superior insulation, ensuring a comfortable living environment while making buildings more energy-efficient.Section 3: Durability and LongevityAnother standout feature of Black Insulation Board is its superior durability and extended lifespan. Traditional insulation materials can deteriorate over time due to factors such as moisture, pests, and general wear and tear. However, Black Insulation Board's advanced composition and construction make it highly resistant to moisture absorption, mold growth, and pest infestations. This durability ensures that buildings remain insulated effectively for years to come, reducing maintenance efforts and costs over the long term.Section 4: Eco-Friendly AttributesIn today's environmentally conscious world, sustainability is at the forefront of every industry. Black Insulation Board excels in this aspect by incorporating eco-friendly materials and manufacturing processes. The product is designed to minimize its carbon footprint, ensuring a reduced impact on the environment. Through its impressive insulation capabilities, Black Insulation Board also aids in achieving energy conservation and reduces greenhouse gas emissions associated with heating and cooling systems.Section 5: Applications and BenefitsBlack Insulation Board finds applications across various sectors, ranging from residential to commercial construction projects. Its versatility allows it to be used in wall cavities, roofs, floors, and basements, contributing to enhanced energy efficiency throughout a building. Additionally, the product's exceptional fire-resistant properties provide an added layer of safety, making it an ideal choice for structures requiring strict fire safety regulations.The benefits of Black Insulation Board extend beyond energy efficiency and sustainability. This advanced insulation material also offers excellent soundproofing capabilities, reducing noise pollution within buildings. Furthermore, its easy installation process and compatibility with different construction materials make it a viable option for both new construction projects and retrofitting existing structures.Section 6: Future Prospects and ConclusionAs the construction industry strives for increased energy efficiency and sustainability, innovative solutions like Black Insulation Board are poised to reshape the insulation landscape. The combination of its exceptional thermal performance, remarkable durability, and eco-friendly attributes positions this product as a go-to choice for architects, contractors, and homeowners looking to create energy-efficient, comfortable, and durable buildings.With ongoing advancements in insulation technology, there is no doubt that Black Insulation Board, alongside other cutting-edge products, will continue to push the boundaries of construction practices. By prioritizing sustainability and embracing these advancements, the construction industry can pave the way towards a greener and more energy-efficient future.

New Film about Life During the Pandemic Released

Title: Pandemic-Inspired Film Spotlights Resilience and Unity in Troubled TimesIntroduction:As the world continues to grapple with the ongoing COVID-19 pandemic, filmmakers have found unique ways to shed light on the challenges, resilience, and unity that have emerged in these troubled times. One such film that has garnered attention recently is a gripping piece aptly titled "Corona Chronicles." While we will refrain from mentioning the specific brand name associated with the film, we will explore the overarching narrative and its relevance within the context of the current global crisis.Section 1: The Concept and Inspiration Behind "Corona Chronicles" (100 words)The brainchild of visionary director [Director's Name], "Corona Chronicles" is an evocative portrayal of humanity's response to the pandemic. Drawing inspiration from real-life stories, the film weaves together narratives of resilience, loss, and hope. Through its characters' journeys, the film aims to encapsulate the collective experience of individuals across the globe, exploring the common threads that bind us together during trying times.Section 2: Capturing the Global Experience (200 words)Utilizing a diverse ensemble cast, "Corona Chronicles" delves into the lives of people from various walks of life, each grappling with their own unique challenges amid the pandemic. From frontline healthcare workers battling exhaustion and despair to essential service providers facing increased risks, the film paints a poignant picture of the collective struggles we have faced and overcome.Moreover, the film depicts the stories of families separated by border closures, individuals adjusting to remote work, and students grappling with the shift to online education. By highlighting these diverse experiences, "Corona Chronicles" aims to foster empathy and understanding across different socioeconomic backgrounds and cultures, emphasizing the shared bonds that unite humanity amidst adversity.Section 3: Themes of Resilience and Unity (200 words)At its core, "Corona Chronicles" offers a message of resilience and unity. The narrative showcases the strength of the human spirit and our capacity for perseverance. Through intertwining plotlines, the film highlights acts of kindness, community support, and individual resilience as beacons of hope during challenging times.The film also explores the impact of technology on our lives during the pandemic, illustrating how virtual connections have emerged as a lifeline to combat physical isolation. It maps the journey from fear and uncertainty to adaptive and innovative approaches, portraying how communities have come together to support one another.Section 4: Independent Production and Distribution in the Film Industry (200 words)"Corona Chronicles" is a testament to the adaptability of filmmakers, who, despite facing numerous challenges amidst the pandemic, were determined to bring their stories to the screen. The film was produced independently, with the cast and crew adhering to strict health and safety protocols.The film's distribution, however, faced hurdles due to theater closures, leading the production team to explore alternative avenues. By partnering with streaming platforms and innovative virtual distribution models, "Corona Chronicles" successfully reached audiences worldwide, allowing viewers to experience the power of its narrative from the safety of their homes.Conclusion:In these uncertain times, "Corona Chronicles" serves as a powerful reminder of the resilience and unity that humanity can muster in the face of adversity. As the global community continues to weather the storm of the ongoing pandemic, films like these play a vital role in fostering empathy, inspiring hope, and reminding us of our shared humanity.

Epoxy Resin Containing Bisphenol A Found to Be Harmful - Experts Express Concerns

Title: Bisphenol A Epoxy Resin: A Revolutionary Addition to the Manufacturing IndustryIntroduction:Established in [year], [Company Name] has paved its way to become a leading innovator in the field of chemical solutions. Renowned for its commitment to quality and excellence, the company has recently introduced an advanced range of Bisphenol A Epoxy Resin, which is expected to revolutionize the manufacturing industry.[Company Name] has been at the forefront of designing cutting-edge solutions that cater to various sectors such as automotive, electronics, construction, and more. With an emphasis on technological advancements and sustainability, the company aims to provide high-performance materials while minimizing the environmental impact. The introduction of Bisphenol A Epoxy Resin aligns perfectly with the organization's vision and commitment.Bisphenol A Epoxy Resin - An Overview:Bisphenol A Epoxy Resin is a robust, versatile, and sustainable material that has gained significant attention in recent years. It is a thermosetting polymer formed by the reaction of Bisphenol A and Epichlorohydrin. Known for its exceptional mechanical properties, electrical insulation properties, and resistance to heat and chemicals, this resin has a plethora of applications across different industries.Key Features and Benefits:1. Superior Mechanical Strength: Bisphenol A Epoxy Resin exhibits exceptional mechanical properties, including high tensile strength and resistance to impact, making it an ideal choice for structural applications.2. Electrical Insulation Properties: The resin demonstrates excellent electrical insulation capabilities, ensuring reliable and safe performance in electrical and electronic devices, such as circuit boards, connectors, and insulators.3. Chemical and Heat Resistance: The inherent chemical resistance of the resin makes it suitable for a wide range of applications involving exposure to harsh chemicals, acids, and solvents. Additionally, its resistance to high temperatures allows it to be used in heat-resistant coatings, adhesives, and composites.4. Environmental Sustainability: [Company Name]'s Bisphenol A Epoxy Resin is manufactured using environmentally friendly processes, adhering to stringent quality control measures. Its recyclable nature further supports the organization's commitment to sustainability.Applications:1. Automotive Industry: The exceptional mechanical strength and heat resistance of Bisphenol A Epoxy Resin make it an ideal material for automotive parts, such as bumpers, body panels, and engine components, providing enhanced durability and lightweight solutions.2. Electronics and Electrical Sector: The resin's excellent electrical insulation properties make it a top choice for manufacturing circuit boards, connectors, potting materials, insulators, and encapsulation of electronic components.3. Construction and Infrastructure: Bisphenol A Epoxy Resin finds applications in the construction industry as a coating material for concrete surfaces, providing protection against chemical corrosion and enhancing the lifespan of structures.4. Aerospace and Defense: The resin's ability to withstand extreme temperatures and its superior mechanical strength make it suitable for use in aerospace and defense applications, including aircraft components, military equipment, and composite materials.Conclusion:The introduction of [Company Name]'s Bisphenol A Epoxy Resin marks a significant milestone in the manufacturing industry. With its exceptional mechanical, electrical, and chemical resistance properties, this versatile material offers a wide range of applications across various sectors. Furthermore, the company's commitment to sustainability ensures that the production of this resin aligns with the growing demand for environmentally friendly solutions. As [Company Name] continues to innovate, the future of manufacturing looks promising with Bisphenol A Epoxy Resin leading the way in revolutionizing industries worldwide.

New Anti-Bacterial Polyester Chip Enhances Protection and Hygiene

New Revolutionary Anti-Bacterial Polyester Chip Unveiled: A Major Leap Forward in Hygiene StandardsIn a world where hygiene and cleanliness have taken center stage due to the ongoing global pandemic, a breakthrough has been made that promises to revolutionize the textile industry. Leading textile manufacturer, [Company Name], has developed an extraordinary anti-bacterial polyester chip that is set to redefine hygiene standards and uphold public health.The newly unveiled anti-bacterial polyester chip, which we cannot yet name due to patent regulations, is a result of extensive research and development carried out by [Company Name]. With years of experience in the textile industry, the company has consistently strived to introduce innovative solutions that cater to the changing needs of the world.Unlike conventional polyester chips, this groundbreaking new variant possesses unique anti-bacterial properties that can inhibit the growth of harmful microorganisms on textile surfaces. Such bacteria, including the notorious E. coli and Staphylococcus aureus, can pose a serious threat to the health of individuals, especially in high-contact areas like hospitals, hotels, and public transport.One of the most significant advantages of this anti-bacterial polyester chip is its enduring efficacy. The inherent properties are not merely sprayed or coated on the fabric surface but integrated within the polymer structure, ensuring long-lasting protection. This means that even after numerous washes, the anti-bacterial functionality remains intact, significantly reducing the spread of harmful pathogens.In addition to its anti-bacterial properties, this polyester chip also exhibits exceptional durability, making it perfect for a wide array of applications. The textile industry can benefit immensely from this innovative product as it opens up new possibilities for manufacturing various products, including bed linens, upholstery, garments, and more. This breakthrough will allow manufacturers to ensure the highest level of hygiene in their products, providing a safer environment for end-users.The development of this anti-bacterial polyester chip aligns perfectly with [Company Name]'s commitment to sustainability and environmental responsibility. The manufacturing process for this revolutionary chip adheres to strict environmental standards, minimizing its carbon footprint and reducing waste. By promoting sustainable practices, [Company Name] strives to play its part in building a greener and healthier future for the planet.With the rising global demand for innovative and effective anti-bacterial textiles, [Company Name] aims to meet the market's requirements and help combat the ever-present risk of infection. By providing a product that combines cutting-edge technology with sustainability, [Company Name] is poised to become a leader in the field of anti-bacterial textiles."We believe that our anti-bacterial polyester chip holds immense potential in transforming numerous industries, from healthcare to hospitality," said [Spokesperson from Company Name]. "Public health is of utmost importance, and our product offers a long-lasting and reliable solution to prevent the spread of harmful bacteria. With this breakthrough, we are confident in our ability to contribute to a safer and healthier world."The unveiling of this anti-bacterial polyester chip marks a significant milestone for both [Company Name] and the textile industry as a whole. It represents a major leap forward in hygiene standards and showcases the potential for innovative advancements within the textile sector. As the world continues to battle the ongoing pandemic, the development of this revolutionary product brings hope and reassurance that a safer and healthier future awaits us all.

New Optical Film for Enhanced Polarization Released

***Please note that I have no access to current news articles or real-time events. The following is a simulated news article based on fictional information and should not be considered factual.***Title: Innovative Optical Pet Base Film for Polarizer Releasing Film Enables Enhanced Display TechnologySubtitle: Revolutionary product from [Company Name] set to revolutionize the display industry[City], [Date] - [Company Name], a global leader in display technology, has announced the launch of its new Optical Pet Base Film for Polarizer Releasing Film. This innovative product is expected to greatly enhance display quality and revolutionize the industry, setting new standards for visual experiences.Optical Pet Base Film is an essential component in the manufacturing of high-resolution displays, including televisions, smartphones, and computer monitors. It serves as the base material for the polarizer releasing film, which is an integral part of the LCD (Liquid Crystal Display) technology. The improved Optical Pet Base Film developed by [Company Name] delivers superior optical performance, allowing for enhanced image quality and increased color accuracy.[Company Name] has long been committed to research and development, striving to push the boundaries of display technology. With the introduction of its new Optical Pet Base Film, the company aims to provide manufacturers with a game-changing solution, offering improved visual experiences for consumers around the world.The new Optical Pet Base Film boasts several features that set it apart from conventional materials. Firstly, its unique composition enables exceptional light transmittance, resulting in brighter, more vibrant displays. This advancement translates to increased sharpness, greater contrast, and more lifelike colors. By delivering deeper blacks and more vibrant whites, displays utilizing this film will offer viewers a captivating visual experience like never before.Moreover, the film's exceptional durability ensures excellent performance in various environmental conditions. It is highly resistant to scratches, reducing the risk of damage and improving the longevity of display devices. This characteristic is particularly significant in the development of flexible displays, where durability is crucial to prevent the material from compromising the overall functionality.The Optical Pet Base Film is also designed to minimize light reflection, ensuring an optimal viewing experience even in brightly lit environments. This feature improves screen visibility and reduces eye strain, making it suitable for prolonged usage and diverse surroundings.As the demand for high-quality displays continues to rise, [Company Name] aims to meet the needs of manufacturers worldwide. With the introduction of the Optical Pet Base Film for Polarizer Releasing Film, the company offers a cutting-edge solution that not only enhances visual performance but also presents an opportunity to revolutionize the entire display industry.[Company Name] CEO, [Name], expressed great enthusiasm about the potential impact of the new product, saying, "Our Optical Pet Base Film is a result of our unwavering commitment to innovation and delivering the best-in-class solutions. We firmly believe that this advancement will reshape the display industry and open up new possibilities for the future of visual experiences."The release of the Optical Pet Base Film marks a significant milestone for [Company Name], heralding an era of unparalleled visual quality. As the industry evolves, [Company Name] continues to pioneer advancements in display technology, solidifying its position as a global leader in the field.With the introduction of this revolutionary product, consumers can expect TVs with more lifelike colors, smartphones with sharper displays, and monitors that deliver an immersive visual experience. The Optical Pet Base Film from [Company Name] is set to transform how we perceive displays, ushering in a new era of enhanced visual technology.About [Company Name]:[Company Name] is a renowned global leader in the development and manufacture of display technologies. With a commitment to innovation and cutting-edge solutions, the company has been at the forefront of the industry for several decades. [Company Name] caters to a wide range of markets, including consumer electronics, automotive, medical, and more. Through its continuous research and development efforts, the company strives to create exceptional visual experiences for consumers worldwide.

What You Need to Know About PVB Film in the News

Polyvinyl Butyral Film: The Future of Safety and SecurityPolyvinyl Butyral Film (PVB) has been increasingly sought after in the construction and automotive industries due to its numerous benefits. It is a transparent material that possesses high strength and elasticity which makes it an ideal choice for enhancing safety and security.PVB is a plastic film that is often used as an interlayer in laminated safety glass. Laminated glass is considered to be the safest option for glazing applications because of its ability to prevent shattering when broken. PVB acts as a binding agent when sandwiched between two panels of toughened glass and makes it difficult for the glass to break into small pieces, reducing the risk of injury or damage.The PVB market is projected to grow significantly in the next few years, with an expected increase in demand from the construction, automotive, and solar industries. According to a report by MarketsandMarkets, the global PVB market size is estimated to reach USD 3.04 billion by 2025, growing at a CAGR of 5.8% during the forecast period.Among the key players in the PVB market, one stands out – V Technical Textiles, a leading manufacturer and supplier of PVB sheet and film. With over three decades of experience in polymer processing, V Technical Textiles has become a trusted partner in the industry. It has established itself as a reliable supplier of high-quality PVB film by providing customized solutions to meet the needs of clients globally.V Technical Textiles is headquartered in Mumbai, India, and has a state-of-the-art manufacturing facility that is equipped with the latest technology. The company has a dedicated team of experts who have extensive knowledge and expertise in the field of PVB film processing. V Technical Textiles’ PVB film is known for its exceptional quality, clarity, and durability, which enables the company to offer competitive pricing and consistent supply to its clients.Apart from its traditional application in safety glass, PVB film has several other uses. It is increasingly being used in solar photovoltaic modules for encapsulation purposes, due to its high resistance to moisture and heat. It is also used in the automotive industry for manufacturing laminated windshields, side windows, and backlights. In recent years, PVB has been utilized in the aerospace industry for aircraft windows. Its unique properties, such as resistance to impact, UV light, and sound, make it an ideal choice for aerospace applications.The demand for PVB film is expected to grow exponentially in the coming years due to its widespread applications. The use of PVB in the construction industry is expected to increase due to safety regulations that require the use of laminated glass in public buildings and high-rise structures. The automotive industry is also one of the most significant end-users of PVB, and with the growing demand for electric vehicles, the usage of PVB is expected to increase further.In conclusion, PVB film is a versatile material that has numerous benefits, including improved safety and security, energy efficiency, and increased durability. The growth of the PVB market is expected to rise significantly in the coming years, and industry experts predict that the demand for PVB film will continue to increase in various sectors. V Technical Textiles, with its unrivaled expertise in PVB processing, is poised to become a market leader in the supply of high-quality PVB film worldwide.

Discovering the Innovative Potential of Liquid Crystalline Epoxy Resin in Manufacturing

Biphenyl Liquid Crystalline Epoxy Resin: A Revolutionary Addition to the Epoxy Resin MarketEpoxy resins are one of the most widely used materials globally, and with good reason – they offer a unique combination of properties that make them ideal for a diverse range of applications. From high-performance coatings, adhesives, and structural composites to electronics, supercapacitors, and even 3D printing, the versatility of epoxy resins knows no bounds.However, with the ever-increasing demand for high-performance materials with improved properties, the search for better and more innovative epoxy resins continues. Enter biphenyl liquid crystalline epoxy resin – a revolutionary new addition to the epoxy resin market that promises to take performance to the next level.What is Biphenyl Liquid Crystalline Epoxy Resin?Biphenyl liquid crystalline epoxy resin, or simply biphenyl LCE resin, is a unique type of epoxy resin that gets its name from the presence of biphenyl molecules within its structure. These molecules possess anisotropic (directionally dependent) properties, making them ideal for creating liquid crystal-type structures that can improve the resin's mechanical, thermal, and electrical properties.In addition to biphenyl molecules, biphenyl LCE resins typically contain other additives that can further enhance their properties, such as reactive diluents, toughening agents, and flame retardants.What Makes Biphenyl Liquid Crystalline Epoxy Resin Unique?The unique properties of biphenyl LCE resins stem from their liquid crystalline structure, which is different from the amorphous structure of conventional epoxy resins. The liquid crystal structure is characterized by long-range molecular ordering, which results in anisotropic properties and improved mechanical, thermal, and electrical properties, among others.More specifically, biphenyl LCE resins exhibit high thermal stability, increased stiffness, and strength, as well as improved electrical conductivity and dielectric properties. These properties make them ideal for a wide range of high-performance applications, such as aerospace, automotive, and electronics.Furthermore, biphenyl LCE resins can be tailored to specific applications by adjusting their composition, such as adding different types of biphenyl molecules or other additives. Additionally, the use of reactive diluents can improve processing and curing times, making biphenyl LCE resins easier to work with than other high-performance resins.The Company Introduction As a leader in the development of advanced materials, {company name} is proud to be at the forefront of the biphenyl LCE resin revolution. With years of experience in resin formulation and customization, {company name} is uniquely positioned to provide high-performance biphenyl LCE resins tailored to specific customer needs, whether it be for aerospace, automotive, or electronics applications.{company name}'s biphenyl LCE resins are produced using state-of-the-art manufacturing techniques, ensuring consistent quality and performance. Our resins are rigorously tested in-house and in collaboration with our customers to ensure they meet or exceed the required specifications.In addition to biphenyl LCE resins, {company name} offers a wide range of advanced materials, including graphene-enhanced composites, polyimides, and carbon nanotubes, among others. Our materials are used in a variety of industries, including aerospace, energy, electronics, and more.ConclusionBiphenyl liquid crystalline epoxy resin is a unique and innovative material that promises to take the epoxy resin market to new heights. With its anisotropic properties and improved mechanical, thermal, and electrical properties, biphenyl LCE resins are poised to become a game-changer in a wide range of high-performance applications.As a leader in the development of advanced materials, {company name} is proud to be at the forefront of this revolution, providing tailored biphenyl LCE resins and other advanced materials to meet the specific needs of our customers.