| Grade No. | Appearance | Softening point /℃ | Convergence rate /s | Pellet flow /mm (125℃) | Free phenol /% | Characteristic |

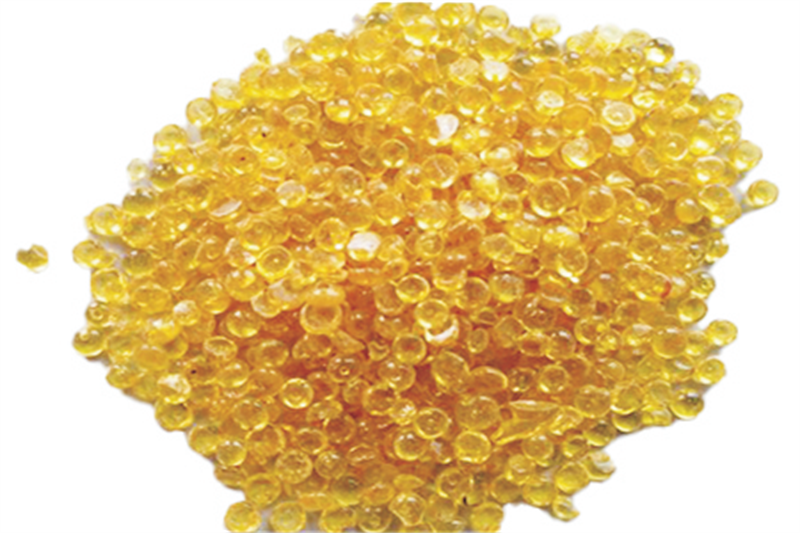

| DR-103 | Uniform faint yellow particles | 90 -93 | 28 - 35 | ≥70 | ≤3.5 | Good polymerization rate / model & core |

| DR-106C | Uniform faint yellow particles | 95 -98 | 20 -27 | ≥45 | ≤3.0 | Good polymerization rate Anti-husking |

| DR-1387 | Uniform faint yellow particles | 85 -89 | 80 - 120 | ≥120 | ≤1.0 | High strength |

| DR-1387S | Uniform faint yellow particles | 87 -89 | 60 -85 | ≥120 | ≤1.0 | High strength |

| DR-1388 | Uniform faint yellow particles | 90 -94 | 80 - 1 10 | ≥90 | ≤0.5 | Intermediate strength Environment-friendly |

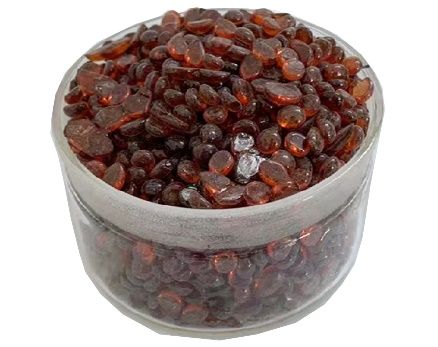

| DR-1391 | Uniform saffron yellow particles | 93 -97 | 50 -70 | ≥90 | ≤1.0 | Cast steel |

| DR-1391Y | Uniform faint yellow particles | 94 -97 | 90 - 120 | ≥90 | ≤1.0 | Cast steel Environment-friendly |

| DR-1393 | Uniform faint yellow particles | 83 -86 | 60 -85 | ≥120 | ≤2.0 | Ultra-high strength |

| DR-1396 | Uniform saffron yellow particles | 90 -94 | 28 - 35 | ≥60 | ≤3.0 | Good polymerization rate Intermediate strength |

Packaging: Paper plastic composite bag packaging and lined with plastic bags, 40kg/bag, 250kg, 500kg/ton bags. Storage: The product should be stored in a dry, cool, ventilated, and rainproof warehouse, away from heat sources. The storage temperature is below 25 ℃ and the relative humidity is below 60%. The storage period is 12 months, and the product can continue to be used after being retested and qualified upon expiration.

Packaging: Paper plastic composite bag packaging and lined with plastic bags, 40kg/bag, 250kg, 500kg/ton bags. Storage: The product should be stored in a dry, cool, ventilated, and rainproof warehouse, away from heat sources. The storage temperature is below 25 ℃ and the relative humidity is below 60%. The storage period is 12 months, and the product can continue to be used after being retested and qualified upon expiration.